VOID FILLING PERTH

BMC are Perth’s specialist Void Filling Company having just completed many major projects. One project was in the rural area, near Northam, and the other in the Perth metropolitan area. BMC was chosen because of its cost effectiveness as well as its ability to get the project done promptly and on time.

What are voids?

Voids are simply holes. However voids can range from very small holes anything up to significantly large voids underground caused by major collapses. It can be necessary to fill these voids to prevent any further damage to existing structures such as railway lines.

Fill out the contact form with as much information related to your projects needs. We will endeavour to reply with a detailed quote within 24 hours.

SAVE 10% TODAY

CIVIL INFRASTRUCTURE APPLICATION

Here at BMC, we primarily use a technique known as permeation grouting to install grout blocks in the ground. Our proprietary microfine cement is mixed with water and plasticiser and then injected into the ground and is recognised as the most cost effective solution in the Australian market. When voids need to be fill that are surrounding critical infrastructure such as roads, runways, bridge approaches and abutments and railway lines, our microfine cement is the preferred choice as the chemicals in our product prevent shrinkage with curing so no voids are left behind. Our techniques and product have been engineered for quick turn around times to minimise downtime. We understand getting the facilities operational again is of the utmost importance.

We also specialise in decommissioning redundant infrastructure such as old underground pipes, manholes, boreholes and more.

MINING APPLICATION

BMC’s high performance GP Void Fill Grout is an Australian designed and manufactured product. Blended using a range of premier cementitous materials, BMC GP Void Fill Grout is supplied as a ready to use powder that requires only the addition of potable water to create a multi-purpose void fill grout.

Our Void Fill Grout is suited perfectly to stabilise soil by filling voids in tunnels and mines. Although our solution is often required under emergency circumstances, we offer routine void filling solutions to ensure downtime is kept to a minimum. Our grout injection solution reduces the number of potential hazards for mine operators by controlling precarious ground.

VOID FILLING CASE STUDY #1

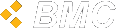

Here we have footage of grout being injected into the ground under a railway line. Pipes which are not dug up will tend to rust over time and cause the ground to sink and become unstable. By injecting our BMC grout, we can fill these voids to keep the ground from sinking..

To Learn More Watch The Video Below

VOID FILLING CASE STUDY #2

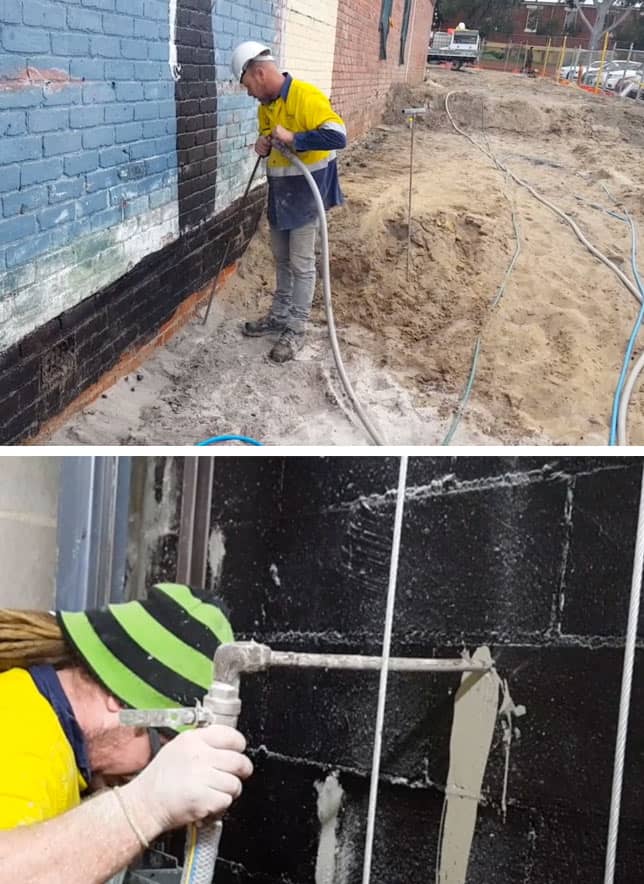

A recent project took us inside the lift shaft of a four story apartment building in Victoria Park. Upon inspection, it was found that some of the bricks were hollow and the requirements of a lift wall specifies that the wall must be solid because of the weight that it is carrying.

As you can see, our technician is drilling holes in to every 3 bricks down. We knew that our BMC Grout Filling mix would flow down into the necessary bricks below and fill the voids. It is a fast drying and hardening mix which sets in a matter of hours. Once the void was filled, we hammered in a bung so that the mix would not flow out.

BMC pumped 1260 litres of grout into the wall over the course of 2 and a half full days including clean-up.

To Learn More Watch The Video Below